03.11.2014

Operational Risk Management (ORM): Five Steps to Enhance Safety, Productivity, and Efficiency

What tools does your company use to enhance safety, productivity, and efficiency? At Faith Technologies, we recently rolled out a new initiative called Operational Risk Management (ORM) that we are pretty excited about.

What tools does your company use to enhance safety, productivity, and efficiency? At Faith Technologies, we recently rolled out a new initiative called Operational Risk Management (ORM) that we are pretty excited about.

What is Operational Risk Management?

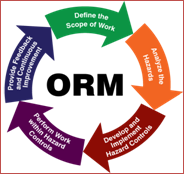

ORM is a simple preplanning process that will be carried out by our field employees as they perform their daily tasks. It will be completed on a daily basis at a crew assembly point or a suitable area on the jobsite, and conducted by a jobsite supervisor. The process is very interactive, and crew members will gather around a whiteboard to discuss and develop a work plan that will identify and control hazards through five core steps. These ORM process steps include:

- Define Scope of Work: This process will require the crew to clearly state the tasks to be performed for the day, as well as review necessary documents (i.e. written procedures, drawings and specifications) to ensure the task is clearly understood.

- Analyze Hazards: This process will require the crew to identify hazards or potential hazards that may arise from the task to be performed.

- Develop and Implement Hazard Controls: Once the hazards have been identified, the crew will then be expected to devise ways of eliminating the hazards by putting certain control measures in place.

- Perform Work Within Hazard Control: This step requires crew members to discuss how work will be performed within the hazard controls identified. Crew members will have to carefully think through their tasks so that they are able to satisfactorily address hazards.

- Provide Feedback and Continuous Improvement: At this stage, supervisors will be expected to regularly review their work processes and provide feedback. Reviews will be made to any deviations from the scope of work or hazard control measures as necessary.

The ORM initiative will shift our focus from traditional Tool Box Talks (TBT) meetings that most times address policies and compliance issues. Unlike TBT meetings where oftentimes workers read prepared topics that may have little or no relevance to their work tasks for the day, ORM is a collaborative process that allows crew members to interact and give feedback on their specific work tasks on a daily basis.

ORM Process and Safety Advantages

Since the process is done on a whiteboard, it serves as a visual reminder for crew members every time they walk past it, eliminates the administrative burden of piling paperwork that comes with TBTs, and overall is very flexible. An advantage of this process is that it is not set in stone, so any change in work conditions will require the crew to reconvene, re-assess, and update their work plan.

When workers are actively involved in the pre-planning process of their work tasks, they are in a better position to identify risks and manage them. They are also more likely to be productive and efficient because their tasks are preplanned and well laid out. At the end of the day, if we could send every employee home safely and at the same time be efficient and productive, we are guaranteed to stay in business for the long haul.

Learn more about ORM and how it can reduce jobsite safety incidents.

If you enjoyed this blog article, please subscribe to stay up to date on the latest industry news from our experts at Faith Technologies.