08.06.2019

Reducing Jobsite Risks Through the Hierarchy of Controls

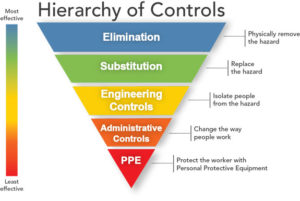

Reducing risks to a level that is considered as low as reasonably practical should be the primary goal of every Occupational Safety and Health (OSH) professional. The use of risk reduction strategy according to the Hierarchy of Controls is one of the concepts used by OSH professionals to achieve this goal. This concept ranks control measures in terms of their effectiveness in controlling or eliminating hazards, the basis being that the control measures at the top of the ranking are more effective than those at the bottom. Inherently safer systems are usually implemented when this hierarchy is followed, which has also led to the substantial reduction in risks of injury and illness.

Different hierarchy of control models have been developed over the years; however, the National Institute for Occupational Safety and Health (NIOSH) through its Prevention through Design (PtD) initiative represents the hierarchy of controls as follows:

Elimination: This requires physically removing the hazard or risk from the system or workplace. It is considered the most effective but most difficult to implement in an existing system. An example could be eliminating a hazardous chemical process from a workplace.

Elimination: This requires physically removing the hazard or risk from the system or workplace. It is considered the most effective but most difficult to implement in an existing system. An example could be eliminating a hazardous chemical process from a workplace.- Substitution: This means replacing the hazard or risk with a less hazardous system. For a similar example, it could encompass replacing a highly hazardous chemical with a less hazardous one.

- Engineering Controls: This means isolating people from the hazard. An example could be installing guards on machines to keep workers away from potential hazards.

- Administrative Controls: This basically means changing the way people work, limiting people’s exposure by adjusting work tasks or schedules. Examples include limiting the time the worker is exposed to a hazard and using warning signs.

- Personal Protective Equipment (PPE): This requires the use of PPE to protect the worker. Though a lot of attention is paid to PPE, it is actually considered the least effective of all the controls.

At Faith Technologies, we believe that reducing risk through the use of the hierarchy of controls is a fundamental way of protecting workers, so we require our workers to implement the control methods in our operational risk management (ORM) daily work briefing. The ORM is a five-step process that ensures every task is analyzed and carried out safely. The third step of this process requires workers to identify hazards associated with their tasks, and devise ways of controlling the hazards. Employees are trained to control all hazards by following the hierarchy of controls in order of effectiveness. They consider fabricating work on the ground to eliminate fall hazards, substitute the use of ladders with lifts where feasible, embed sleeves in slabs to prevent core drilling, rotate jobs among employees, use caution signs, and always engage PPE as the final line of defense against hazards.

The use of the hierarchy of controls should be at the core of all risk-reduction strategies. Emphasis should always be placed at the top of the hierarchy, which requires eliminating or substituting the hazard when feasible. There is no doubt that when effectively implemented, this hierarchy helps create a safer and healthier workplace.

Is the use of the hierarchy of controls part of your company’s risk reduction strategy?

If you enjoyed this blog article, please subscribe to stay up to date on the latest industry news from our experts at Faith Technologies.